Pluritank

PLURITANK 10/12P

Ultrasonic cleaning plant with 5 detergent tanks

PLURITANK 22/12P

Ultrasonic cleaning plant with 5 detergent tanks

PLURITANK 45/12P

Ultrasonic cleaning plant with 5 detergent tanks

PLURITANK 95/8P

Ultrasonic cleaning plant with 3 detergent tanks

PLURITANK L(X)/(Y)P

Ultrasonic cleaning plant built to customer specifications

EUROCOLD is also known for producing the traditional in line multi-tanks cleaning system, which belongs to the machine series PLURITANK. These cleaning lines are made on customer request only and designed according to the kind of products requiring the treatment. This system is based on cleaning processes using water and aqueous detergents. Each cleaning process can be customized such as the process parameters of each single tank. The line is designed to clean a large quantity of material in different shape and size from chips, chemicals, cooling oils, dust, etc.

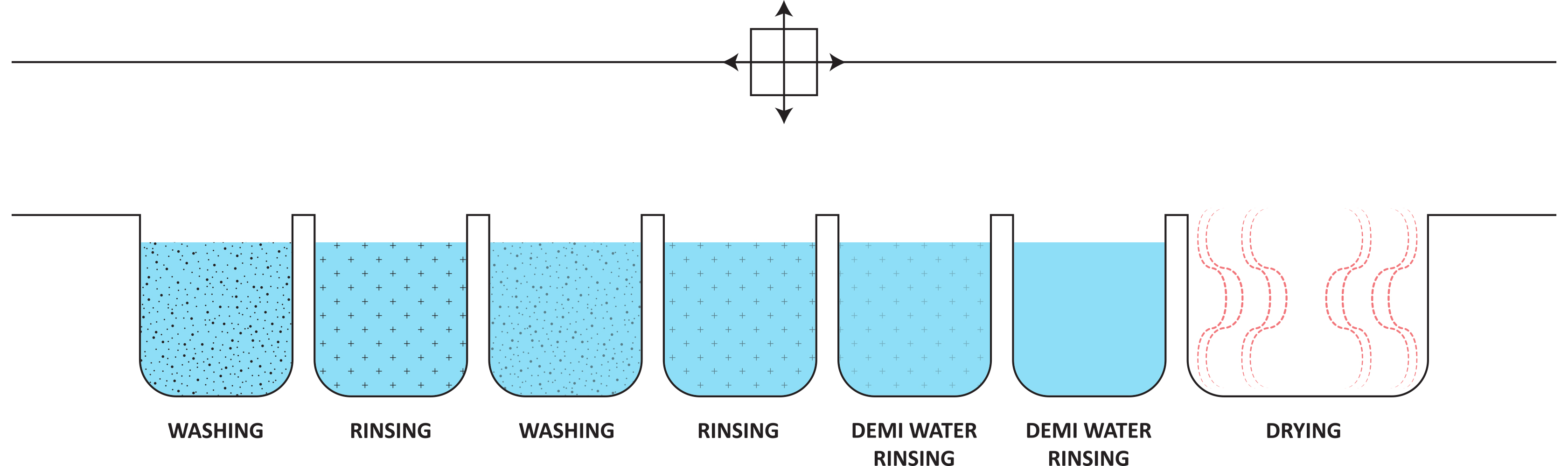

See below a possible layout:

The products to clean are brought from one tank to the other by a dedicated basket and a two axis robot. Number of tanks, such as such type of features in each tank, changes according to machine design. In each tank only one phase at a time is run and cleaning time for each product is identical. This washing system cleans products surface and ensures that the amount of remaining dirt – measured according to ISO 16232 and with the support of electronic scansion magnifier – is minimal so it is compatible for surface treatment processes like PVD, CVD, PECVD, CHROMATE, CROMIZING, etc.

PLURITANK cleaning line:

- Is a multi-tank machine; in each tank one phase only of the cleaning process is performed. Thanks are arranged in groups to facilitate machine assembling in place. Machine, depending of number of tanks, requires up to two-three days to be installed and ready to start

- is built only on customized requests

- can clean products from few grams and millimeters to some decimeters and kilograms.

- has low environmental impact

- rinsing tanks are designed in cascades to minimize water consumption

- SW is designed to satisfy “Industry 4.0” requirements

- its HMI is easy to use and helpful